In this article, we are going to explore some of the newer technologies that companies explore and use within their business models.

Technology used in operational models:

There are 2 technologies companies have started infusing into their operational models to become better, faster and cheaper. The first one is the Internet of Things, also known as IoT. This is essentially a network of connected objects that are aware, autonomous and actionable.

Case study of IoT

Large Scale Commercial Farm

To illustrate this, I’ll use an example of a client of ours, large scale commercial farm, that is operated within the SADC region. They have a large plot of approximately six hectares, all housed within a greenhouse environment. Within this greenhouse environment, we have placed multiple sensors and multiple platforms that are powering the sensors. These sensors record fundamental data, including the soil level, the water levels in the soil and oxygen levels on a daily basis. This data is collected and sent to a platform that analyses this data in real time. Hence, for example, if the water level is too low in a particular plant, it then instructs the water pump to open the water and water that specific plant.

This ensures that every single plant is accounted for in terms of what it needs to grow. When we look at the Internet of Things in the organisations, we will find that organisations are using and leveraging on this these kinds of platforms to ensure that they can be able to do away with repetitive tasks that individuals or people are had to do in the past. They are now able to have sensors and autonomous platforms do these tasks instead. This kind of technology can also be seen in the use of self-driving cars. These cars have different types of sensors that sense what is going on in their immediate environment, process those observations and make decisions autonomously.

IoT as a Tool for Growth

How can organisations leverage on IoT to find and capture their value and increase growth? Many different organisations have used this technology in different ways. But typically, IoT is most prevalent in manufacturing companies, where there are a lot of different variables involved that determine the total output. IoT has been noted to work successfully within farms, and, as of late in insurance. I’ll give a good example once again with a client of ours from the insurance sector. They have recently implemented a platform that allows them to be able to determine how much in premiums their clients should pay on a monthly basis depending on their behavior.

This platform essentially monitors the client’s driving throughout the month, records the data and then analyses the good and bad behavior and produces the monetary value the client should be charged in premiums for the respective month. This kind of technology will continue to evolve as years go by, with different organisations using it in different contexts and in different ways. However, organisations need to be very careful when implementing this technology because it’s still very new. Due to this newness, very few parts of the value chain will be easily interconnected. As a result, organisations need to ensure that whatever IoT platforms they integrate have a modular architecture that enables them to be able to make edits and modifications, as well as platforms with easy to use API’s, which will ensure that they’re able to connect these platforms to other platforms as they become available.

Additive Manufacturing (3D Printing)

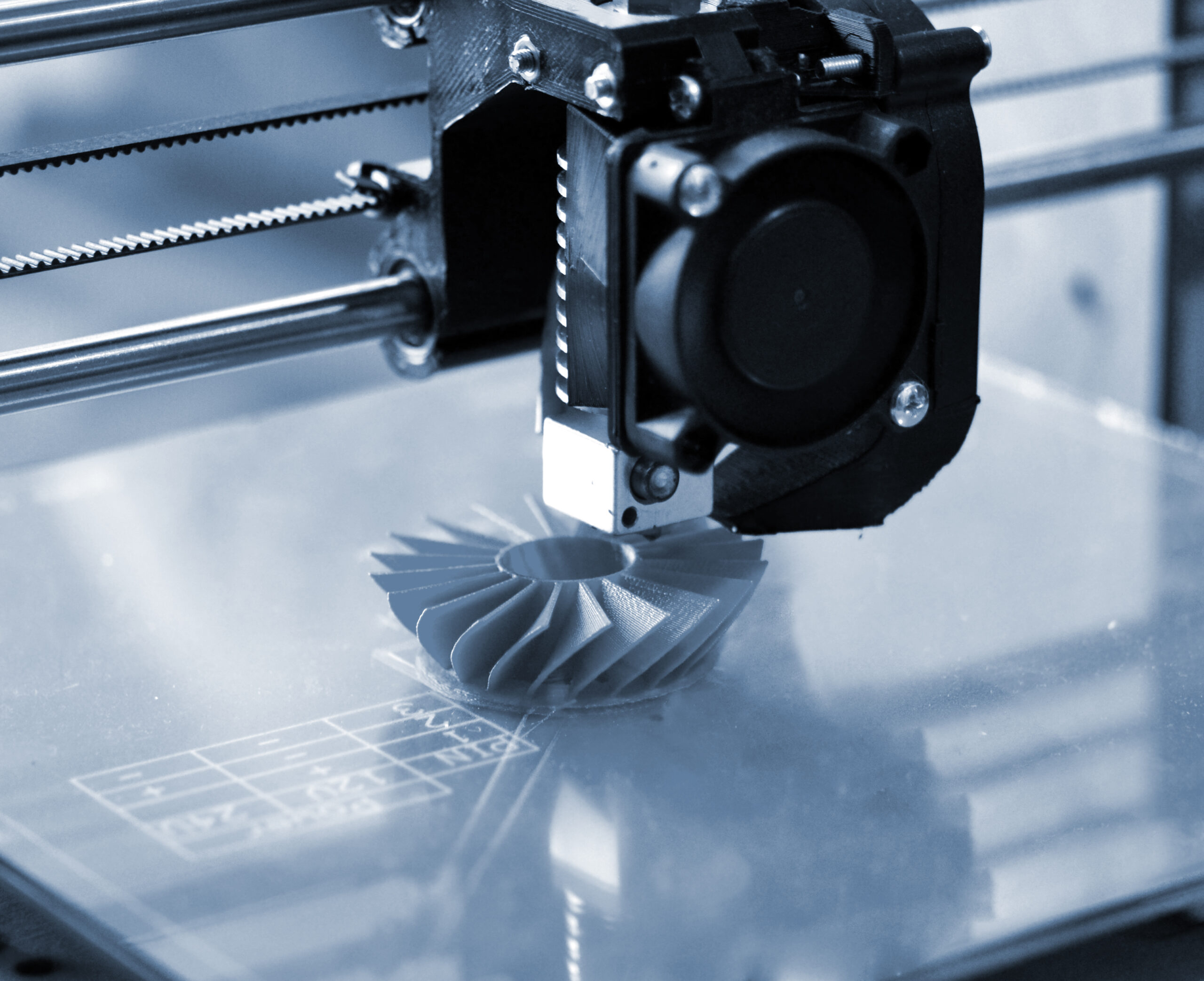

The next technology to explore is additive manufacturing, also known as 3D Printing.

It is essentially the creation of three-dimensional products using computer aided design, layering and different types of materials. This type of manufacturing builds on various layers of materials until a finished product is created; where traditionally, if wanted to make a table, you would use a large block of wood, cut it into the desired shape, and assemble the table, leaving out the remaining wood you don’t need anymore. Additive printing focuses on creating the specific thing that you’d like to create using fine powder and the design that you input into the machine. Therefore, where organizations would normally have to wait for large sums of materials in manufacturing, they do not have to do so thanks to this technology.

3D Printing in Construction

To illustrate this, I’ll give an example of an organisation in Zimbabwe. This organisation is a large cement manufacturing organisation that has traditionally made most of their profit in the household market. However, they realize that with the advent of 3D printing, they might find themselves in a trap going into the future. This prompted them to transition towards 3D printing. Today, they use 3D printing to create Computer Aided Models of houses, and then going on to print them. It sounds ridiculous, how organisations and people can now print an entire house, but it has been tried and tested multiple times. Organisations such as this one are saving approximately 40 to 60% on the costs that they would have traditionally had. This novelty has completely demolished traditional business models that organisations had before.

3D Printing in Health

Another great example is organizations in the United States of America that are currently using 3d printing to create body parts. Yes! Body parts! For example, if an individual’s arm has to be amputated, now they are able to use 3D printing to create a personalized arm for the individual to use.

All this has been made possible by the fact that 3D printers have become cheaper, more accessible and more affordable to individuals and organizations to use.

How it affects your firm

So, how does this affect your business? Say for example, you’re a manufacturing company and you’d like to introduce a new array of products. Normally, with traditional printing, you would have had to order the different supplies you needed, and then use them to create a prototype of what you want to build. However, with the advent of 3D printing, you can simply create a 3D model of what you’d like to build and print this model from your 3D printer, provided that you have the materials required to make this model. This means that your firm can create prototypes at a much cheaper price, and produce different prototypes much faster than it would have been in the past. Furthermore, because this kind of technology makes it easier and faster to manufacture, you can easily personalize products for your customers, and reduce your total costs in manufacturing, since the additive printing uses only the material that is required to create that one product. The reduction of costs is from the reduction of wastage in the printing process. However, organisations need to note that this kind of technology is not yet working at an optimal rate for large scale manufacturing businesses. It is still in its infancy. This technology is most useful in organisations that need a high degree of customization to their product, a high degree of flexibility to their product, as well as a high degree of specificity in how it is designed and created. As a result, organisations that have adopted these technologies in these markets have seen up to 60% reduction in costs over time, leaving their competition far behind in terms of their production rate and from a cost perspective.

Now that we’ve looked at some of the technologies that organisations are using now, the next stage is to look into the future, in terms of what organisations will be using tomorrow. These are some of the things that we at Xavier Africa Technologies are experimenting and tinkering with on a regular basis in our various products. Join us next week as we discuss some of these experimental technologies that we’ve been using, as well as how they can be able to help you and your organisation thrive in this environment.